1. Giriş

This manual provides essential information for the safe operation, maintenance, and troubleshooting of your MechMaxx 0831V 8x16 Inch Mini Metal Lathe Machine. Please read this manual thoroughly before operating the machine to ensure proper use and to prevent injury or damage. Keep this manual accessible for future reference.

Figure 1.1: The MechMaxx 0831V Mini Metal Lathe Machine with various tools and accessories.

2. Güvenlik Talimatları

Always prioritize safety when operating any machinery. Failure to follow these safety guidelines can result in serious injury or damage to the equipment.

- Göz Koruması: Always wear safety glasses or a face shield to protect against flying debris.

- Uygun Kıyafet: Avoid loose clothing, jewelry, and long hair that can get caught in moving parts.

- Çalışma Alanı: Keep your work area clean, well-lit, and free of clutter. Ensure adequate space around the machine.

- İş Parçasını Güvenli Hale Getirin: İş parçasının her zaman güvenli bir şekilde kapatıldığından emin olunampMakineyi çalıştırmadan önce aynaya veya penseye takın.

- Acil durdurma: Acil durdurma butonunun yerini ve çalışma şeklini öğrenin.

- Güç Bağlantısının Kesilmesi: Herhangi bir ayarlama, bakım veya aksesuar değişimi yapmadan önce elektrik bağlantısını kesin.

- Machine Guards: Ensure all safety guards are in place and functioning correctly before operation.

- Kılavuzu Okuyun: Do not operate the machine until you have read and understood all instructions and warnings in this manual.

Figure 2.1: Safety warning labels on the machine, including a caution against changing belts while running and general PPE requirements.

3. Bileşenler Bittiview

The MechMaxx 0831V metal lathe consists of several key components designed for precision metalworking.

- Başlık: Houses the main spindle, motor, and speed control mechanisms.

- Chuck: Holds the workpiece securely. This model features a 1.5-inch spindle bore.

- Kuyruk mili: Supports the far end of long workpieces and can hold drilling tools.

- Taşıma: Moves along the bed, carrying the cross slide and tool post.

- Cross Slide: Moves perpendicular to the lathe bed, allowing for facing operations.

- Compound Slide: Rotates and moves for angled cuts and fine adjustments.

- Takım Tutucu: Holds the cutting tools.

- Lathe Bed: The main frame providing a stable base for all components, featuring double-V ways for precise movement.

- Kurşun vida: Otomatik besleme ve diş açma işlemlerinde kullanılır.

- Kontrol Paneli: Includes power switch, emergency stop, and speed display.

Figure 3.1: The 1.5-inch spindle bore of the lathe chuck, allowing for larger diameter stock to pass through.

Figure 3.2: Detailed specifications for the tool post, including maximum tool bit size (15/32"), cross slide travel (3-1/2"), and compound slide travel (2-3/4").

Figure 3.3: The double-V ways design of the lathe bed, ensuring stable and accurate movement of the carriage and tailstock.

4. Kurulum

Proper setup is crucial for the performance and safety of your lathe.

- Paketin açılması: Carefully remove the lathe and all accessories from the packaging. Retain packaging for future transport or storage.

- Atama: Place the lathe on a sturdy, level workbench or an optional stand. Ensure it is securely fastened to prevent movement during operation.

- Temizlik: Remove any protective coatings or grease from the machine surfaces using a suitable cleaner. Lubricate all moving parts as indicated in the maintenance section.

- Güç Bağlantısı: Connect the machine to a grounded 110V AC power outlet. Ensure the power switch is in the 'OFF' position before plugging in.

- İlk Muayene: Check all bolts and fasteners for tightness. Ensure all components move freely without excessive play.

Figure 4.1: The lathe machine shown mounted on an optional stand (SKU: 510001A), providing a stable and ergonomic working height.

5. Kullanım Talimatları

This section covers the basic steps for operating your MechMaxx 0831V lathe.

5.1 Güç Açma ve Hız Kontrolü

- Ensure the emergency stop button is disengaged (pulled out).

- Turn the main power switch to 'ON'.

- The lathe features variable speed control (0-2500 RPM). Adjust the speed using the control knob.

- The machine has two speed ranges: 'A' (Low Speed: 0-1250 RPM) and 'B' (High Speed: 0-2500 RPM). Select the appropriate range based on your machining task and material.

Figure 5.1: The accurate speed display showing current RPM and the selection for low (0-1250 RPM) or high (0-2500 RPM) speed ranges.

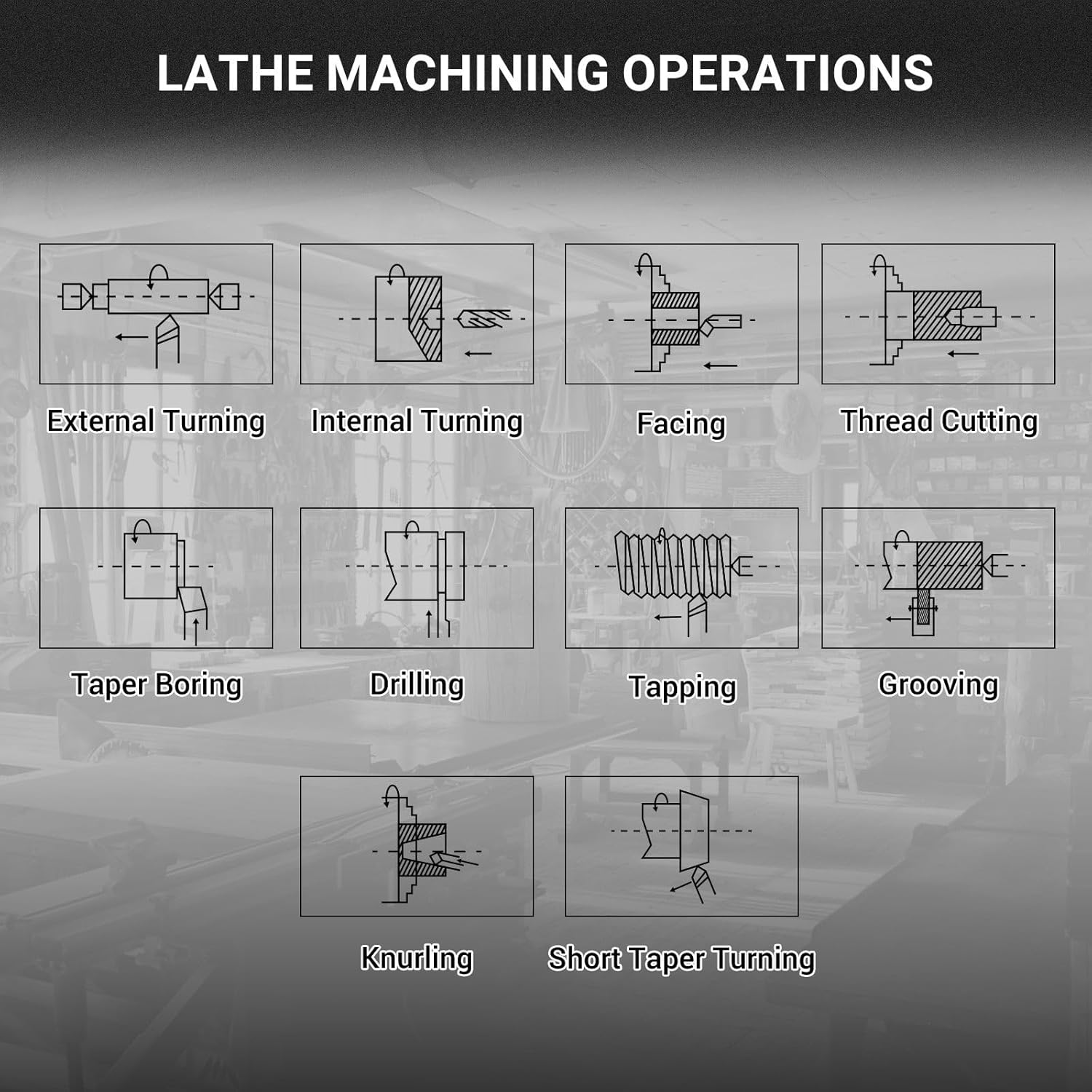

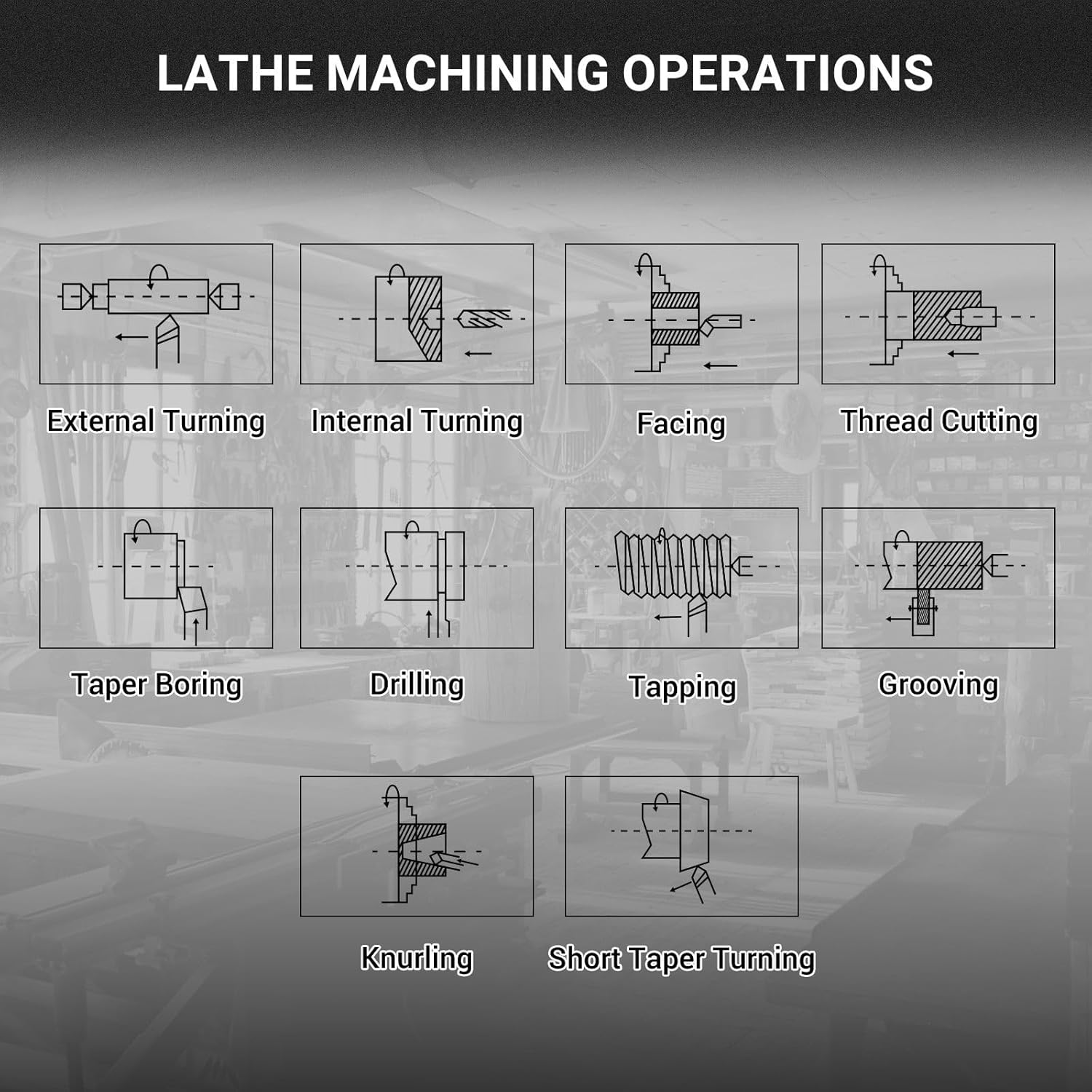

5.2 Basic Machining Operations

The lathe is capable of various operations, including:

- External Turning: Bir iş parçasının çapını küçültmek.

- Internal Turning (Boring): Enlarging an existing hole.

- Yüz: Creating a flat surface perpendicular to the spindle axis.

- İplik Kesme: Creating external or internal threads using the lead screw and appropriate gears. The thread dial indicator assists in precise thread engagement.

- Taper Boring/Turning: Creating conical shapes.

- Delme: Creating holes along the workpiece axis using the tailstock.

- Ritme ayak uydurmak: Cutting grooves into the workpiece.

- KnurlTürkçe: Creating a textured pattern on the workpiece surface.

Figure 5.2: Visual representations of common lathe machining operations, including external turning, internal turning, facing, thread cutting, taper boring, drilling, tapping, grooving, knurling, and short taper turning.

5.3 Precision Adjustments

The handwheels for the cross slide and compound slide are graduated for precise material removal. Each increment on the handwheel typically represents 0.01 inch of travel.

Figure 5.3: The handwheels feature clear markings for 0.01 inch increments, allowing for accurate depth of cut and positioning.

6. Bakım

Regular maintenance ensures the longevity and accuracy of your lathe.

- Temizlik: After each use, clean the machine thoroughly, removing all chips and debris. Use a brush or vacuum; never use compressed air directly on moving parts as it can force chips into bearings.

- Yağlama: Regularly lubricate the lathe bed ways, lead screw, and other moving parts with appropriate machine oil. Refer to the lubrication points indicated in the machine diagram (if available).

- Kemer gerginliği: Periodically check the drive belt tension. Adjust if necessary to prevent slippage or excessive wear. Always disconnect power before checking or adjusting belts.

- Denetleme: Routinely inspect all components for wear, damage, or loose fasteners. Tighten or replace parts as needed.

- Depolamak: When not in use, cover the lathe to protect it from dust and moisture.

7. Sorun Giderme

Bu bölümde, torna tezgahınızla karşılaşabileceğiniz yaygın sorunlar ele alınmaktadır.

| Sorun | Olası Neden | Çözüm |

|---|---|---|

| Makine başlamıyor | No power; Emergency stop engaged; Loose wiring | Check power connection; Disengage emergency stop; Inspect wiring (with power disconnected) |

| Motor runs but spindle does not turn | Drive belt broken or loose | Inspect and replace/tighten drive belt (power disconnected) |

| Yanlış kesimler | Loose tool post; Worn cutting tool; Unstable workpiece; Loose gibs | Tighten tool post; Replace/sharpen tool; Secure workpiece; Adjust gibs |

| Aşırı titreşim | Unbalanced workpiece; Loose mounting; Worn bearings | Balance workpiece; Securely mount lathe; Inspect and replace bearings if necessary |

8. Özellikler

Key technical specifications for the MechMaxx 0831V Mini Metal Lathe Machine:

| Özellik | Şartname |

|---|---|

| Model Numarası | 0831V |

| Yatak Üzerinde Salıncak | 8-1/4 inç |

| Merkezler Arası Mesafe | 15-3/4 inç |

| Mil deliği | 1.5 inç |

| Motor Gücü | 1.5 HP (Fırçasız) |

| Mil Hızı | 0-2500 RPM (Variable, two ranges) |

| Cilttage | 110 Volt AC |

| Çapraz Kaydırak Seyahati | 3-1/2 inç |

| Bileşik Slayt Seyahati | 2-3/4 inç |

| Maximum Tool Bit Size | 15/32 inç |

| Threading Capability | Metric and Inch threads |

| Ürün Ağırlığı | 190 pound |

| Ürün Boyutları | 12.2 x 4.92 x 7.87 inç |

9. Garanti ve Destek

For warranty information, technical support, or to purchase replacement parts, please contact MechMaxx customer service. Refer to your purchase documentation for specific warranty terms and contact details.

You can also visit the official MechMaxx store for additional product information and support: MechMaxx Mağazası